Borehole deformability tests are used for in-situ modulus measurements in boreholes. Instrument setups can be broken down into two groups according to the area of application: Low pressures and long displacements are required in soils, high pressures and relatively short displacements in rock. The following methods exist to meet the particular requirements:

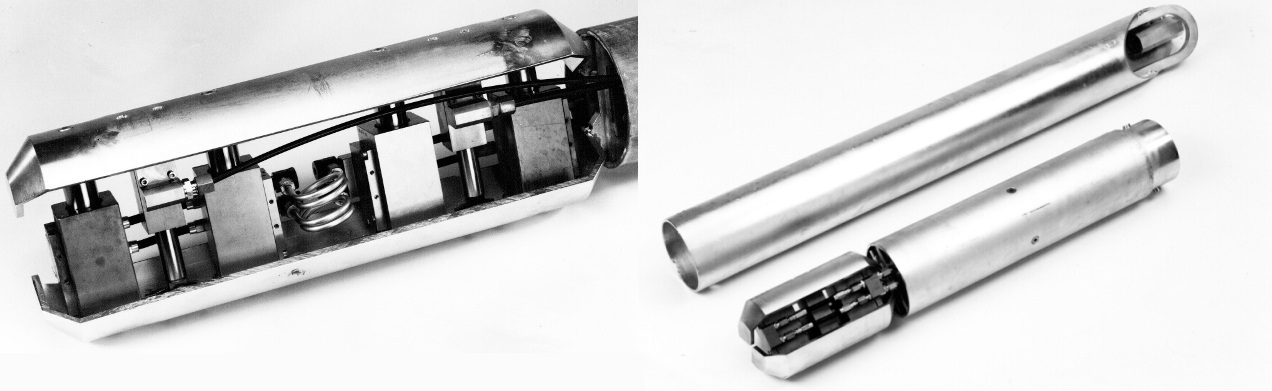

- Hydraulic cylinders combined with clamshell-type loading plates and electric displacement transducers (borehole jack devices)

- Hose packers with volumetric determination of borehole deformability (Ménard pressuremeter)

- Hose packers combined with electric displacement transducers

(flexible dilatometer)

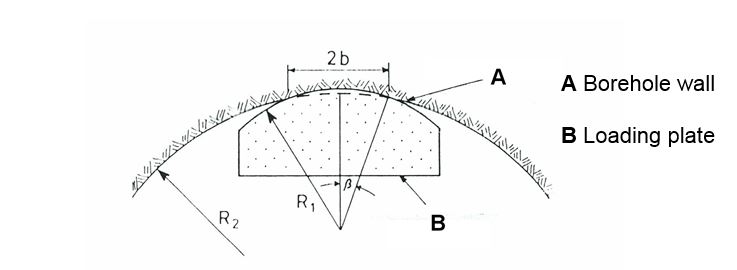

The advantage of first solution is the high pressures that can be applied by way of the cylinders. Its disadvantage, particularly in rock, are the clamshell-type loading plates, which have to be adapted exactly to the borehole diameter because otherwise the hydraulic pressure will only be transferred to the borehole wall as a linear load. Swolfs and Kibler (1982) as well as Shuri (1981) drew attention to this problem, after which the use of this type of probe in rock declined notably (see Fig. 1).

Fig. 1 Incomplete contact between loading plate and borehole wall in a borehole with a radius bigger than the radius of the loading plate camber

(from becker, 1985)

In soil and soft rock, on the other hand, the loading plates can press themselves into the foundation, ensuring complete contact with the surroundings.

This type of probe is available in three different diameters:

- Goodman probe (borehole diameter 76 mm)

- Ettlinger borehole jack device 101 (borehole diameter 101 mm)

- Ettlinger borehole jack device I-II/146 (borehole diameter 146 mm)

The Goodman probe is built for a borehole diameter normally used for exploration drillings particularly in the Anglo-Saxon area. The probe's great advantage of being able to apply high pressures to the borehole wall is offset by the disadvantage of a measuring path of just 5 mm with a reading accuracy of 0.01 mm. It is a contradiction of design that the probe should have enough force to test rock with high and extremely high spring constants yet its displacement measuring system has a reading accuracy (as opposed to measuring accuracy) of just 0.01 mm. On the other hand, if this probe is used in less hard rock, its measuring path of 5 mm will be completely insufficient for applying higher probe pressures and hence exploiting the probe's advantages. If you add this drawback to the above mentioned effect of the contact between loading plate and borehole wall being incomplete, and if you also consider the small borehole diameter to be a disadvantage, then you have to conclude that the Goodman probe is now obsolete in terms of engineering and rock mechanics.

Our response to these contradictions and shortcomings was the development of two borehole jack devices for a borehole diameter of 101 mm and one for 146 mm. They cover a measuring path of 40 and 50 mm with a reading accuracy of 0.001 mm. The probe forces are designed for use in less hard rock and soil. The probe diameter of 101 mm was chosen in particular for those geological situations where the vicissitude of the rock calls for a quick decision after completing the preliminary borehole as to whether to conduct a borehole jack test or a flexible dilatometer test. Formerly this option was not available.

The second variation of the borehole deformability test was introduced to soil mechanics as the pressiometric method according to Ménard. The borehole wall is subjected to radial-symmetric loading, which represents a more positive mechanical loading of the soil than the clamshell-type loading of variant 1. With large deformations (i.e. in soils), measurement of the change of diameter is fairly reliable and very economical. With small changes of diameter in solid rock, on the other hand, the method produces unsatisfactory results because its measurement of deformations is too imprecise.

The third variation listed above has scored good marks, particularly when combined with exploration boreholes of diameter 146 mm (SK6L). With this type of test, the borehole wall is again subjected to radial-symmetric loading. A probe diameter of 95 mm is an advantage because this enables its use in combination with the wire line core barrel SK6L and a preliminary borehole diameter of 101 mm. A smaller probe diameter is undesirable for reasons of rock mechanics.

This type of probe, also known as a flexible dilatometer, is ideal for tests in rock with uniaxial strengths ³ 25 MPa because the hose packer adapts to the actual borehole diameter and complete contact between the probe and borehole wall is assured even with irregular wall surfaces. The two other test variants, on the other hand, are mainly used in soils (uniaxial compressive strength £ 1 MPa) and rock of very low strength (with a uniaxial compressive strength between 1 and 25 MPa) where full contact between probe and borehole wall is assured after a short nestling phase, which is usually well reflected in the test diagram.

If we also assume that the general structural loads of our structures lie between 0 and 4 MPa, there will be an obvious interest in using probes that are also able to determine the in-situ modulus in this load range.

The complete description of Borehole Deformability Testing can also be downloaded here as pdf.