Just a few years ago it was still customary to collect geotechnical data by hand. The introduction of automatic data acquisition has led to a major revolution in metrology, to its advantage certainly but also to its disadvantage in some respects. When using these technologies we should always remain aware of their limits while appreciating their benefits: No automatic measuring system is able to replace an engineer's power of judgement.

The above remarks should not be interpreted as a vote against the use of automatic data acquisition systems. Rather, they reflect the belief that the suitability of such systems should be subjected to honest assessment before they are put into service. The advantages and disadvantages of automatic data acquisition are listed in Tab. 1.

|

Advantages |

Disadvantages |

|

|

Tab. 1 List of the advantages and disadvantages of automatic data acquisition (according to Dunnicliff, 1988)

The typical components of an automatic data acquisition system are:

- An electric sensor or transducer which scans the physical variable to be measured

- A measuring point selector

- A measuring amplifier which converts the sensor signal into a signal that can be processed by an analog-digital converter

- A converter which converts the measurement signal into a form that can be collected by a microprocessor

- A microprocessor (control computer) which selects the measuring points and collects and saves the data

- A recording unit (hard disk, diskette, magnetic tape, printer) which stores the measured data

- A monitor

- A printer

- A plotter

If required:

- A remote data transmission system

Optional:

- Lightning protection for all the electrical components

The range of data acquisition solutions available from gif can be divided into three systems, albeit the boundaries between each are blurred:

- Standalone system

- Master-slave system

- Online system

Standalone system

The standalone system is used to collect data from a small number of locally grouped sensors over the medium to long term. The measured data is scanned and saved, and it is collected by remote data transmission or cable. See Section 6.1 Decentral data acquisition.

Master-slave system

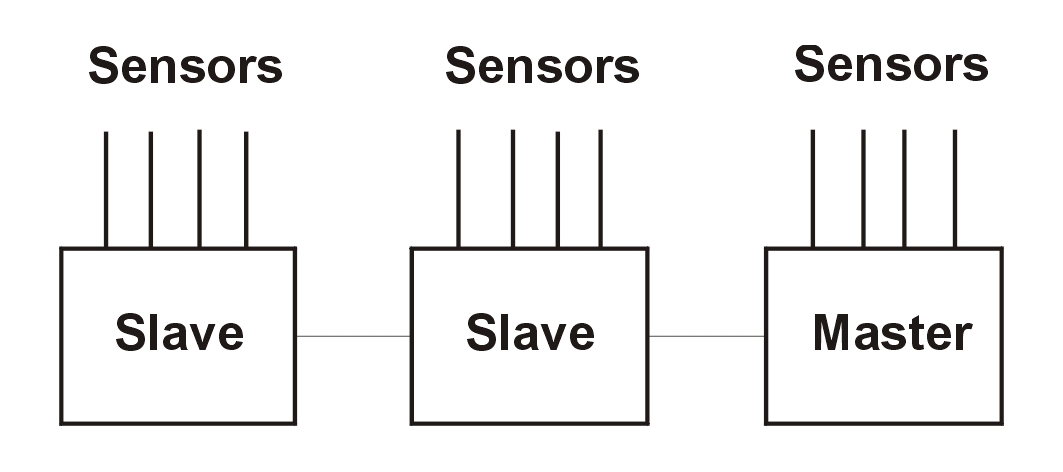

Master-slave systems are used for a larger number of sensors and/or great distances between the sensors. Communication between the master and slaves takes place via a 2‑ to 6‑wire line, depending on the transmission standard and whether the voltage is supplied through the same line. Remote data transmission, e. g. via radio or optical cables, is also possible.

Fig. 1 Example of a master-slave system setup

Der Master initialisiert die Slaves und holt ihre erfassten Daten ab. Mit Hilfe des Masters können die Daten ausgewertet oder auf ein anderes Rechnersystem übertragen werden. Die Slaves können auch vor Ort mittels eines Laptops bedient werden. Der Vorteil von Master-Slave Systemen liegt u. a. darin, dass die Kabellängen zum Sensor sehr kurz gehalten werden. Dies bewirkt eine geringe Störanfälligkeit des Messsignals bzw. auch des gesamten Messsystems, da Störungen lokal bleiben und nicht in einer Messzentrale zusammengeführt werden. Oft sind solche Systeme auch vom Verkabelungsaufwand günstiger. Beispielhafte Anwendungsgebiete sind Tunnelbauwerke, Bergwerke, Staudämme und Deponien.

The master initialises the slaves and collects the data they have scanned. With the help of the master the data can be evaluated or transferred to a different computer system. It is also possible to hook into the slaves in-situ with a laptop. The advantage of master-slave systems is that cable lengths to the sensors can be kept very short. This minimises the interference susceptibility of the measuring signal and the overall measuring system, because disturbances stay local and are not accumulated at a central measuring station. Often systems of this type also require less cabling effort. Typical fields of application are tunnelling, mining, dams and dumps.

Online system

The online system is designed for high-speed processes requiring continuous inspection. The measured data is scanned and displayed in graphic form simultaneously. Sometimes the system is equipped with a slave as the control computer of hydraulic or pneumatic systems. Cases of application include:

Borehole jack tests, pile load tests, plate load tests and shear tests.

All systems can be set up to generate an alarm when limit values are passed.

The complete description of Automatic Data Acquisition can also be downloaded here as a pdf.