Developments in underground engineering - as well as in the rest of civil engineering - have resulted in as much use as possible being made of the rock's co-bearing capacity. This is achieved through the composite action of the rock and the actual structure.

Rock behaviour depends on a number of poorly quantifiable factors, particularly due to their complex interaction. Stability verifications and structure behaviour forecasts based on calculations or model tests need to be viewed, therefore, with all due caution.

The deformations and shifts of stress, which arise as a rock's response to the excavation of a cavity and the delayed installation of supports, cannot be determined with satisfactory accuracy using traditional statics and strength theory. Stability verifications need to be supplemented and counter-checked, therefore, with measurements.

In modern tunnelling and cavern engineering, the aim is to make as much use as possible of the rock's co-bearing properties. To do so, rock deformations need to be controlled in such a way as to mobilise a protective sheath on the one hand while accepting a weakening of the rock on the other hand. The better this succeeds, the higher will be stability and efficiency. This aim is most likely to be achieved if foundation measurements and structure measurements are an integral part of the construction method used (see: L. Müller and E. Fecker, Fundamental Ideas and Principles of the "New Austrian Tunnelling Method"). Deformation, stress, displacement and force measurements perform the following functions:

- They provide information about the actual behaviour of the rock or composite structure (rock and sheeting) as a function of all the respective factors related to the rock, construction method, operating mode, etc.

- They enable the stability to be assessed and the geotechnical basis of the design and calculations to be checked

- Furthermore they enable specification of support systems and help to insert the sheeting and lining

- They enable the assessment of the size of the inner shell for a double wall structure

In addition to performing the above functions, which have a direct bearing on the planned gallery, tunnel or cavern structure, it is necessary to monitor existing buildings and installations when executing flat underground structures in developed areas.

Measurements taken in so-called main measuring sections are needed to provide information about rock and sheeting behaviour in conjunction with different rock conditions, construction methods and construction operations in order to assess

- the effectiveness and efficiency of the support systems and heading method used,

- the basis of the design and calculations,

- stability,

- danger to other buildings and installations.

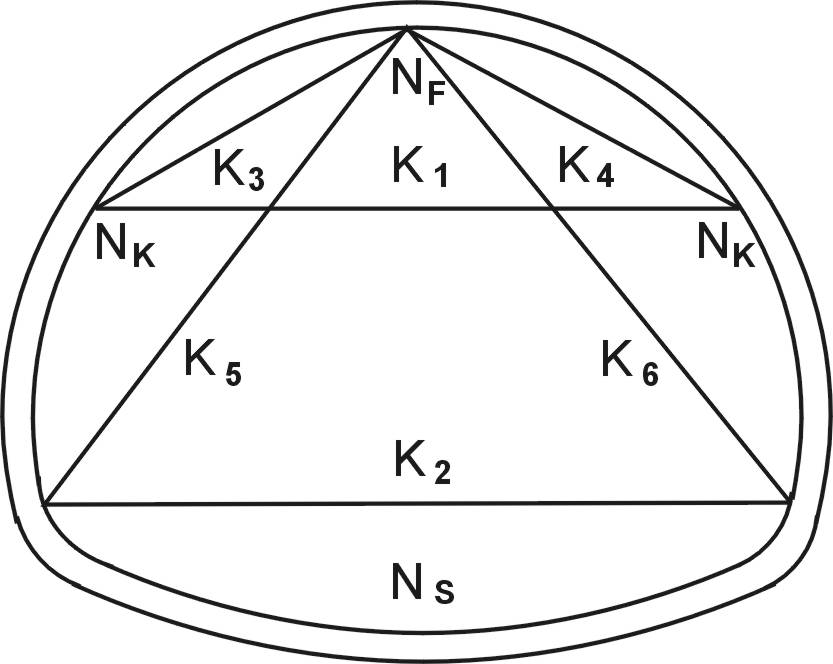

The following figure is an example of a main measuring section for a double-wall transport tunnel to be constructed in accordance with the New Austrian Tunnelling Method. The scheduled measurements are:

K - Convergence measurements

H - Height levelling measurements in the tunnel and on the ground surface

E - Extensometer measurements

I - Inclinometer measurements

G - Rock pressure measurements

B - Concrete pressure or concrete deformation measurements

A - Anchor force or pressure measurements

Fig. 1 Main measuring section for a transport tunnel (measurements during the construction period; convergence and levelling measurements in the tunnel are not shown)

The measurements taken in the standard measuring sections of a tunnel project are intended to enable the construction operations and support work to be adapted to the particular conditions and the degree of stability to be assessed.

Measurements in standard measuring sections should be quick and easy to take, and they must provide information concerning the stability of the driven cavity. From the measurement results it must be possible to identify the time-related trend in the redistribution of stresses and to detect whether and when stabilisation of the excavated and supported cavity is achieved.

Measurements planned for standard measuring sections should also be conducted in the main measuring sections because a realistic, comparative interpretation of results from the standard measuring sections is only possible in conjunction with the more extensive data collected in the main sections.

Convergence and levelling measurements have proven to be suitable for assessing the stress conditions of the sheeting and - by comparison with the measurement results from the main measuring sections - of the surrounding rock.

Fig. 2 Standard measuring section for a tunnel with calotte heading

For biddings of geotechnical measurements we recommend the following points:

- Bidding of boreholes for extensometers and inclinometers according to length and diameter.

- Bidding of delivery of particular instruments according to the number of pieces and, if need be, according to the specified type.

- For multiple extensometers the length of the particular extensometers must be assessed, not only the total length.

The installation of the instruments must be bidden according to the number of pieces. The necessary grout must be paid according to consumption. Respective positions must be assigned. - Outage times for the installation of instruments should be paid according to the needed time. Respective positions must be assigned.

- Outage times for the execution of measurements as well as times for making available lifting ramps including the necessary staff should be paid according to the needed time. Respective positions must be assigned.

The validity of measurements depends mainly on the careful installation of the instruments which are partly very expensive. Hence this should be left to specialised firms. The installation must be controlled by the buyer; it has to be documented by the aid of photos and drafts. Especially the overbreaks, the thickness of the sheeting and the geological situation must be recorded graphically.

The measurements should be executed and evaluated from the geotechnical consultant of the buyer resp. from his representative, because he is directly involved in the construction works and thus will be able to reduce disruptions to a minimum.

The buyer, his expert and he who performs the commission should interpret the results together. Only from a quick evaluation and entry of the results in diagrams you can draw conclusions to the construction operation and to the stability, from which the efficiency of the structure will profit.

According to the execution of the particular measuring types we can say the following:

Levellings and convergence measurements can be executed quickly and at reasonable prices. We recommend not to have too high demands regarding the precision of these two measuring types, but to install a large number of measuring sections. By the aid of these sections you can permanently control if the selected support measures are sufficient and if the heading velocity is well chosen. An increase of the velocity often leads to a reduction of the displacements.

In tunnelling close to the surface divergences have often been measured. This means, that you must dissociate from the idea of an arching around a tunnel near to surface. In deeper zones the divergences predominate. Furthermore the convergence measurements show that immediately after the foundation has been concreted the displacements in the support are finished - provided it was well constructed.

A comparison with measurements of extensometers, installed from the outside before the tunnelling, shows that the displacements measured by levelling and convergence are always smaller than the actually arising displacements. In most of the cases 50 ‑ 80 % of the displacements have been faded away until setting the fixed points. Often measured end displacements of the roof are about 50 mm, at the same time the measured convergences amount to between 10 and 50 % of the roof’s settlements.

If within a few days after the excavation the roof’s settlements exceed a value of about 1/300 of the width of the calotte foundation, additional support systems like re-anchorage are necessary to fade away the settlements.

Inclinometer measurements in conjunction with tunnelling projects as shown in Fig. 1 are only suitable when large displacements - at least 20 mm - are expected. In case of smaller displacements the errors in measurement often conceal the reality.

Support stresses are demonstrated by stress measurements. An often observed mean value of the concrete stress amounts to 25 bars in case of a small cover, in case of a larger cover between 50 and 100 bars. The rock stresses usually amount to 1/10 until 1/20 of the concrete stresses. The measuring ranges of the rock and concrete stress transducers are to be dimensioned accordingly.

As a rule the measured stresses are smaller than the values supposed by static calculation. From this you can gather that in general the system rock/support has enough safety reserves.

Especially from the stress measurements you can see that some favourable factors as working method, heading velocity, etc. cannot be calculated. A comparison with the time-related convergence value shows that the stress changes are not finished even a long time after having passed the measuring section, while the displacements are or should be finished after the foundation has been concreted.

The complete description of geotechnical measurements in tunneling can also be downloaded here as a pdf.