In view of the potential risk to the environment from waste storage schemes, it is absolutely essential to provide for continuous inspection of the physical behaviour of a dump's body and that of its surroundings, particularly its sealing elements, and for the scanning of possible chemical changes in the ground water.

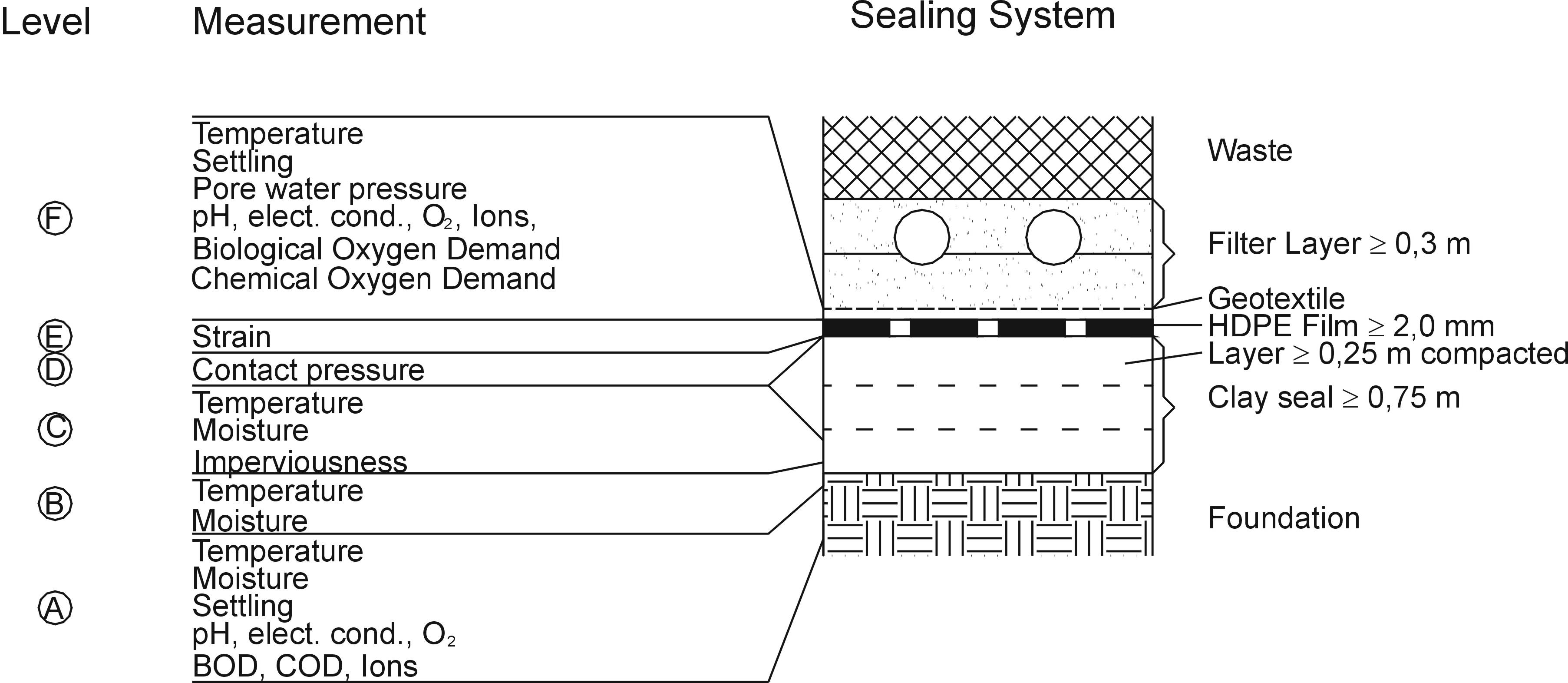

A base sealing system that complies with today's statutory regulations will require taking mainly those measurements listed in Fig. 1 for the long-term scanning of safety-critical operating data.

Fig. 1 Measurement to be taken in the base sealing system of a refuse dump (according to Reuter, 1989)

Measurements in the side sealing system are similar except that lateral displacement measurements are carried out instead of settling measurements, and strain measurements in the HDPE film take on special importance because here the film may be subjected to far higher loads than in the dump base, depending on the gradient of the side slope.

In addition to taking safety-critical settling measurements it is important for settlement of the dump base to develop uniformly and in accordance with expectations in order to comply with the nominal gradient specified for the drainage lines. Local settlements may lead, for example, to water being held back in the pipes where the solids entrained in the seepage water form deposits. Sinking of the dump body must also be monitored for the following reasons:

- A dump's service life can only be estimated from time-related monitoring of the waste's compaction

- Recultivation can only be planned on the basis of a reliable settling forecast

- Design of the surface sealing system must take account of the settling characteristic

- Forecasts of the final extent of settling require evaluation of the waste and soil mechanics, which is only possible after taking regular settlement measurements on the dump body.

Up to now, wide-scale settlement measurements were not possible until after the dump was filled. Today high precision settlement measurements can be easily performed by photogrammetry (Gertloff, 1990). Measurements of the base settlement characteristic were completely impossible. With hydrostatic methods for measuring the height of pipes it is now possible to scan settlement profiles over the entire length of a drainage or degassing pipe. A dense settlement profile grid can be obtained when the pipes are closely spaced and horizontal degassing pipes are installed at several height levels.

Using these methods the drainage system should be checked

- directly after installation (acceptance inspection)

- after filling in the first layers of waste

- at yearly intervals during use

The settlement characteristic of a dump body must also be monitored, of course, in accordance with the specific terms of reference. The extent of a dump body's settlement depends inter alia on reaction processes and the site's growth; it may be sensible, therefore, to carry out settlement measurements at shorter intervals in order to be able to make a more reliable forecast.

One of the compulsory duties of dump supervision is to measure the total volume of seepage water. At the same time it makes sense to check periodically the amount of discharge from the various drainage pipes. A comparison of the amounts of water issuing from the various lines is a first pointer to partial failure of the drainage system. Evaluation of the total discharge of seepage water in conjunction with meteorological data (temperature, precipitation, air moisture) provides the basis for monitoring the dump's water regime. This and comparisons with other dumps can reveal, under certain circumstances, irregular storage and retention processes.

The most expedient approach is to conduct continuous measurements of the seepage water volume with simultaneous readings of its electrical conductance and pH-value.

This joint logging and evaluation of parameters allows you, for example, to conclude whether large quantities of rain water are entering the system. If the amount of seepage water rises immediately after the commencement of precipitation and if this is accompanied by a parallel drop in conductance, checks should be carried out to see whether unpolluted rain water is getting into the drainage system. The continuously scanned data can be evaluated online by digital data acquisition and computer processing systems.

Seepage water analysis is the most important method alongside dump gas analysis for the monitoring of dump emissions. It is required not only for the planning and control of the seepage water treatment system but also for the detection of reaction processes in the dump body. Extensive full-scale analyses as ordered by the supervisory authorities are generally conducted only on samples of seepage water discharged from the dump as a whole or on samples of seepage water from individual stages of the dump's construction.

Normally the build-up of seepage water inside a dump body goes unnoticed until seepage water escapes uncontrolled from the base or slope area or it is revealed in the course of construction activities. Here, too, regular checks with piezometers are required. Steps should be taken, therefore, to equip each filled section or, in the event of lengthy filling breaks, every partly filled section with probes to check the build-up of seepage water on the dump base. Sinking the probe after installing the waste is preferable to pulling up the probe simultaneously as the latter leads to irregular, insufficient compaction of the waste in the area of the probe. On the other hand a borehole after the dump is filled may lead to a leakage in the base sealing system; this explains why such boreholes are only admissible by way of exception.

The probes are to be of filter design only at the dump base end; otherwise they must be designed as a continuous tube in order not to detect any false water levels caused by gas pressure or the build-up of water due to impervious layers inside the dump body. The bottom of the probe should be approximately 1 m above the seal. The only material that should be used for the tube is plastic (HDPE). The tube diameter should not be smaller than 4" in order to allow for seepage water samples to be taken with a submersible pump.

At least three monitoring probes should be installed per dump section in order to identify the alignment of the water surface. The exact arrangement and number of probes depends on the size and layout of the drainage system.

The water levels in the probes are to be recorded continuously with a level logger or central data acquisition system; temperature, pH-value and electrical conductance are scanned simultaneously.

Temperature measurements in dumps are the exception nowadays. According to Ramke (1987), however, there are a number of reasons why it can be an advantage to know the temperature and temperature characteristic:

- Thermal loading of the pipelines affects their fatigue strength. A knowledge of the temperature characteristic at the dump base enables the size of the pipes to be selected with greater accuracy.

- The temperature of the outflowing seepage water is important for the design of seepage water treatment systems.

- In conjunction with other parameters, the temperature characteristic inside a dump body enables a better understanding of the processes of decomposition.

- Temperature gradients (vertical and horizontal) may be co-responsible for the formation of deposits in the drainage system.

- In slag and special waste dumps, temperature readings help to reveal undesirable reactions in the dump body.

Knowledge of the temperature characteristic is thus a parameter that could be needed directly for the operation of a dump and which plays an important role particularly in the planning of refuse dumps and in the understanding of relationships.

The complete description of Geotechnical Measurements in Dump Engineering can also be downloaded here as a pdf.